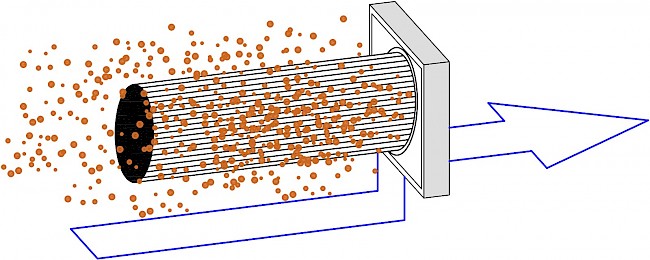

Vibrating bag filter system

Vibrating bag filter system with a suction capacity of up to 2,000 m³/h.

designation | description | usage | suction perfomance | power rating | ec-ventilation | suction collector | pre separator integrated | filter area | accessories | data sheet |

|---|---|---|---|---|---|---|---|---|---|---|

| DL 900 N S | Indirect construction via hose/pipe connections with dust drawer | Dust | 900 m³/h | 750 W | - | X | - | 4,5 m² | Link | |

| DL 900 N T | Indirect construction via hose/pipe connections with dust bin | Dust | 900 m³/h | 750 W | - | X | - | 4,5 m² | Link |

designation | description | usage | suction perfomance | power rating | ec-ventilation | suction collector | pre separator integrated | filter area | accessories | data sheet |

|---|---|---|---|---|---|---|---|---|---|---|

| DL 2000 N S | Indirect construction via hose/pipe connections | Dust | 2.000 m³/h | 2.200 W | - | X | - | 10 m² | Link | |

| DL 2000 N T | Indirect construction via hose/pipe connections | Dust | 2.000 m³/h | 2.200 W | - | X | - | 10 m² | Link |